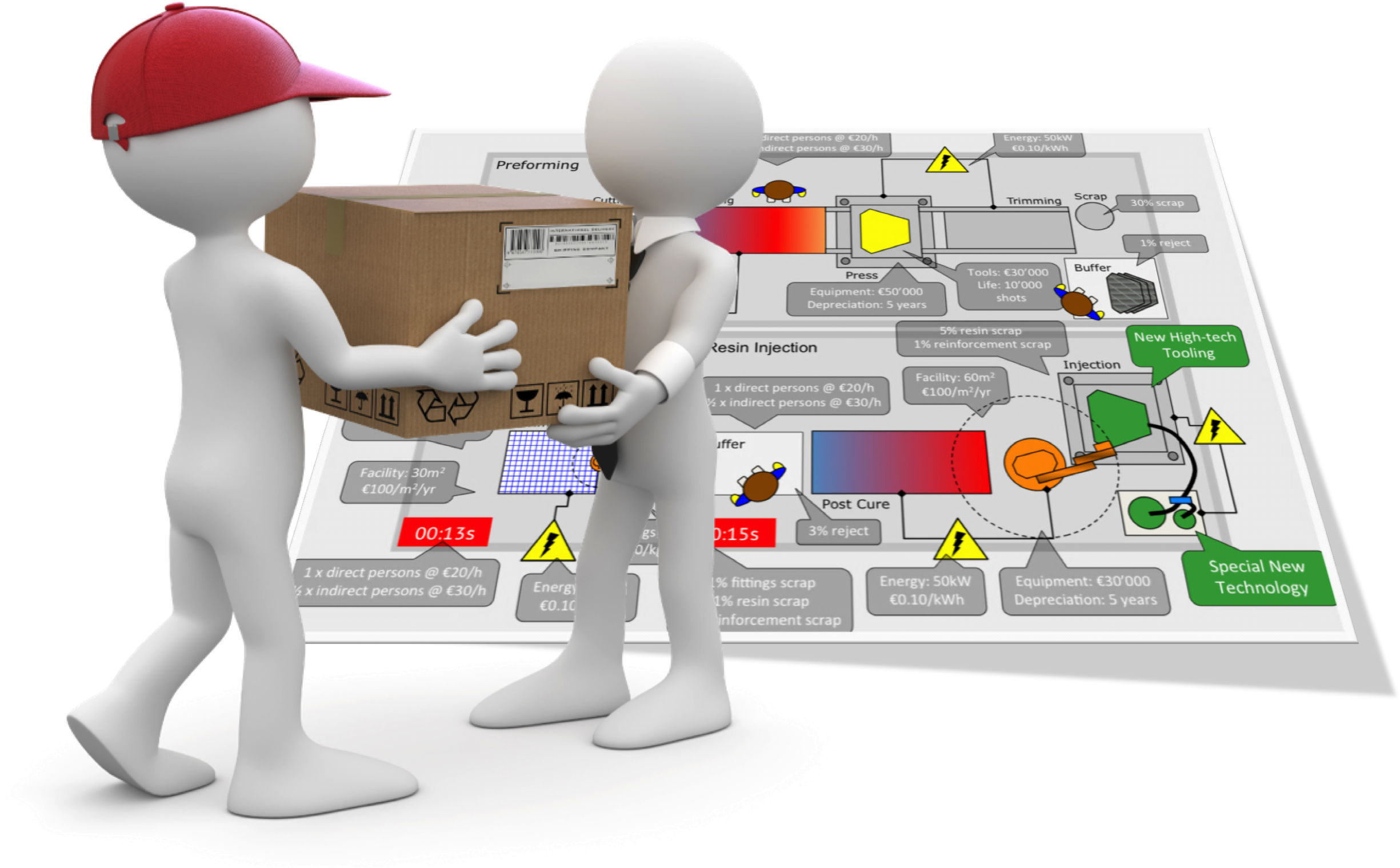

InCA includes functionality for incorporating complex process flow with built-in or user-defined cost calculations and is designed specifically for like-for-like comparison of different materials, equipment and processes.

Integrated analysis tools enable visualisation of parameter sensitivity, comparison of alternatives and evaluation of different manufacturing scenarios. InCA can also be used to optimise resource utilisation, investment in equipment and tooling and to quantify the potential return on investment from R&D activities or new technology.

Use InCA in the cloud or on your own internal server, facilitating collaboration internally or on joint development projects between companies. Suppliers can share models with potential customers to show the value of their unique products. OEMs can compare "like-for-like" different options from a range of suppliers.